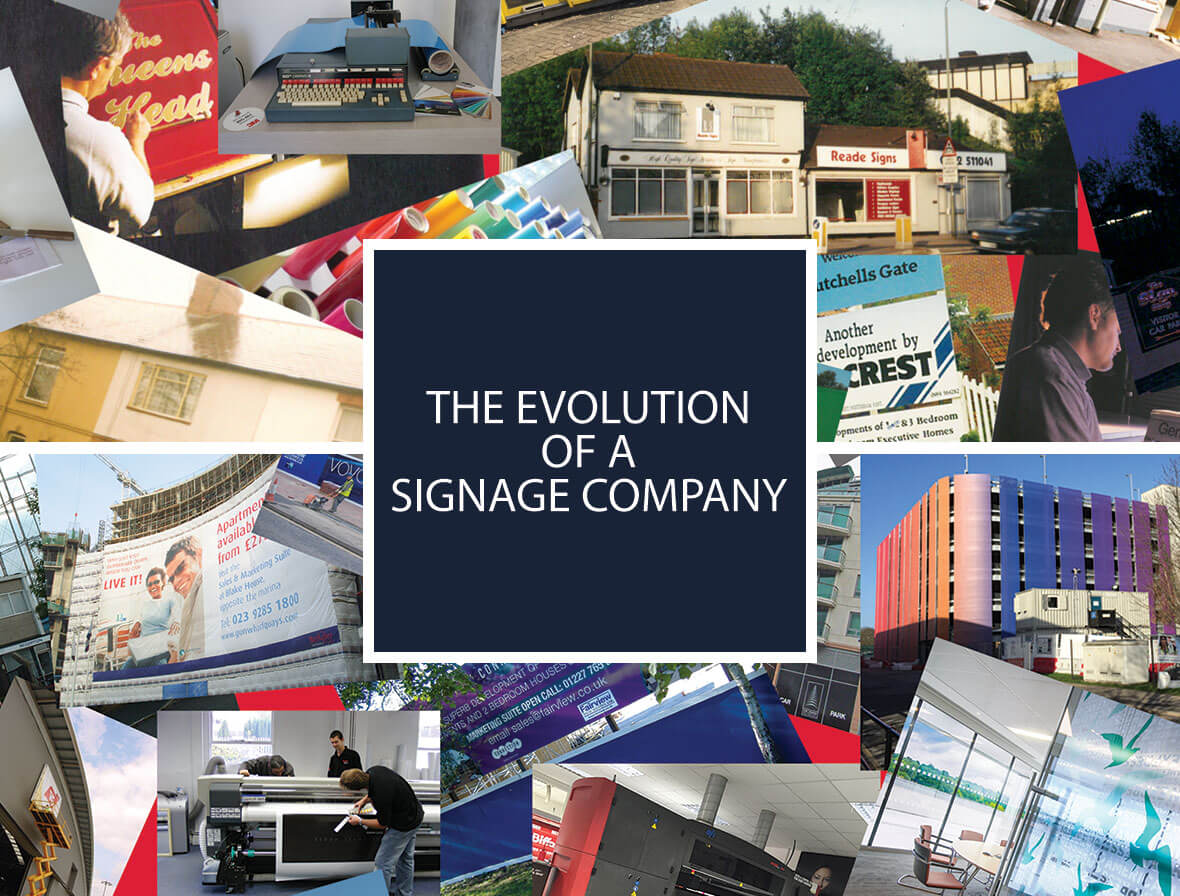

Since Reade Signs was founded in 1980, the once time-intensive craft of sign writing has changed beyond recognition. Hand-made signs have morphed into large-format branded graphics produced using the latest printing technology. Hand tooling has been replaced by CNC machines. And health and safety requirements mean ladders are out and cherry pickers are in. Here, we look back at the early days of Reade Signs and reflect on what has – and hasn’t – changed about the signage industry.

£100 and a few tins of paint

Andy Reade, CEO, founded Reade Signs from his spare bedroom with £100, a few tins of paint and a couple of sheets of plywood. After leaving school he became an apprentice sign writer for a local one-man-band sign company, eventually moving to the Royal Aircraft Establishment in Farnborough. A lack of fulfilling work spurred Andy into action and he started to take extra jobs at the weekends and evenings, soon building a customer base and eventually setting up on his own.

Sign writing is a true skill. In the early days, Andy hand-painted timber signs, shop front fascia signs, vehicles and all types of different surfaces, including glass, painted timber and metal using specialist paints and traditional techniques. There were cut vinyl letter systems available, but back in the 1980s, these systems were basic with limited fonts and slow production times. However, the systems improved quickly, and the writing was literally on the wall for hand painted signage as a mass production method.

During the first three years, Andy moved from back-bedroom to garden workshop crafting signs for shop fronts, vehicles, job boards, builders and pubs – enjoying the variety of jobs and clients. As the business grew, Andy took on an apprentice himself and after ten years, Reade Signs moved to its first premises in Ash Vale, followed by several more moves as the business quickly expanded.

Roots and wings

It was during this time that Andy Fergus Smith joined, bringing a complementary set of skills to the team to help the company grow. Originally a graphic designer, he ran his own screen print business for 12 years before joining Reade Signs in 2002 as production manager. He was involved in graphic design, account management, operational and general management before becoming Director and shareholder in 2008.

In 2003, Reade Signs moved to its current two-floor office space and factory at Holder Road in Aldershot. At the time there were 15 employees, and this has now grown to over 40; with specialist teams bringing wide-ranging skills, qualifications and knowledge and including some loyal, long-standing employees and members of the Reade family.

Rapid developments in technology meant that sign writing evolved and expanded. The lines blurred between print and sign making and the possibilities for large format outdoor graphics to suit all budgets opened up new markets for sign makers. Full colour, photographic printing onto vinyl was a real breakthrough. All of a sudden you’d see images on vehicles, building site hoardings and temporary banners, where previously it would have been prohibitively expensive to have graphics on these platforms. Direct-to-media flatbed printers marked the next step enabling bigger, faster and higher quality printing onto substrates as diverse as ply and glass. Reade Signs invested in direct-to-media technology in the mid noughties and as the company continued to grow, so did the size of the clients. It was the booming property sector that Reade Signs really gained expertise in and today site signage, hoarding, marketing suites and directional signage remain at the core of our offering.

The signage industry – what’s changed

1. Signage rebranded

The signage industry has changed beyond recognition and the terminology used has had a bit of a rebrand in recent years; signage is now seen as a core channel in the marketing mix and an important part of achieving brand consistency. Knowledge of marketing and brands is vital to understand unique brand requirements and innovate. It’s frequently referred to as large scale brand implementation, brand activation, wayfinding or large format branding… or just plain signage.

2. Super graphics

Sign making has always been a craft, but in terms of scale, the industry has blossomed. There are very few screen printers and only a handful of artisan sign writers today; work centres more around implementation and management of projects, with multiple stakeholders and suppliers. From local beginnings, clients now come from all over the country. A baffling array of different formats are available for all types of signage, banners, hoarding, events and exhibition graphics, retail branding, vehicle graphics and marketing suites. Professional, quality signage is now available to any organisation and to suit any budget. The art of sign-making still requires a specialist skill-set, but the skills needed are very different.

3. Specialists – all under one roof

Over the years, as sign requirements reached a larger scale, a finished sign would require several specialists at different points throughout the process. You’d get the signage artwork agreed, then go to a sign writer, then an artist for the pictorial part, then you might go to a screen printer. Now, technology and an expert in-house team means this is all under one roof. We have a large pool of skills, qualifications and knowledge from a team expert at quoting, sourcing and project managing to meet client demands and be increasingly competitive.

4. Choice and demands

As larger companies and brands realised the importance of making a splash with signage, expectations become higher and lead times got shorter. Reade Signs now works with so many more materials – it’s not just ply and paint – there are hundreds of materials that can create different effects to represent a brand and grab the audience’s attention. It used to take weeks to apply undercoat, paint the ply, route-out posts – it was all quite laborious. But now, full colour capabilities mean we have no constraints – we can print onto almost any material. Last year we produced six miles of panels for property developers, handled over 2,500 jobs and every day we have up to 20 installers out on the road. And from receipt of final artwork to installation on-site, we can fit 20m hoarding in just 72 hours.

The changing face of business and the economic impacts of the last 30 years mean clients are far more cost conscious and demand value for money from their marketing spend. The good news is that modern materials and printing techniques enable us to provide high-end finish using cost-effective materials to maximise any budget.

5. ‘Up a ladder in shorts and flip flops!’

There wasn’t much in the way of health and safety when Andy founded the company. He’d install signs ‘up a ladder in his shorts and flip flops – you would make things happen!’ For a long time now, though, we’ve been finding solutions to make it happen safely and observe strict regulations, taking regular advice from our own health and safety consultant. Training and accreditation is so important to being highly professional and maintaining high standards at every stage of the design, manufacture and installation process.

The signage industry – what hasn’t changed?

1. It’s all still marketing

Essentially, signage is still marketing; we might use more elaborate brand and marketing terminology, but it still serves the same purpose. ‘Brand activation’ is the art of driving consumer action – and was the same intention when creating a hand-crafted sign for The Red Lion! Our purpose is to make brands and messaging stand out, the industry sometimes just uses different terminology.

2. Reputation

As a business, our reputation still supports us in the same way it did from day one and has helped us grow our work with many national property developers and corporates. The service level requirements and quality control are still as high as ever and reputation enables us to continue to be creative and branch out into other exciting fields – beyond shop fronts to large-scale architectural signage projects and complex wayfinding solutions.

3. Apprenticeships

Andy started out as an apprentice sign maker and that’s something we continue to embrace as a company; it’s vital to invest in the future and pass skills on to a new generation. Continuous development and training is very much at the heart of the business – not just our passion to do a job well, but also the necessity to keep up with changing technology. Continuing the family theme of the business, we currently have two brothers working in production department, who joined as apprentices and show a real aptitude to learn, improve and work as part of our team. In fact, one of them recently won Young Sign Maker of the Year!

4. Passion for design

Andy Reade has always had a passion for design and this still is a driving force within the company as the market for large scale graphics and digital signage grows. While the business is unrecognisable from the company Andy founded, he’s keen to see it grow and progress to the next generation. It’s this passion, being flexible and constantly evolving that’s always been essential in the signage industry. For us, constantly improving and trying new things means short deadlines can be met, problems can be overcome with creative solutions and adjustments to changing situations can be managed smoothly.